Best Of

Introducing Q Assist:Context-aware Gen AI underpinned by the Quantexa Decision Intelligence Platform

At QuanCon 2025 in March we announced that the first release of Q Assist was coming out of a pilot phase and would soon be made available to license for both existing and new customers. Q Assist is now available in Early Access and can be deployed in solutions and platform deployments on version 2.7.

So, what is Q Assist?

Q Assist brings Generative AI capabilities to our Decision Intelligence Platform and the solutions we offer at Quantexa. It is a modular platform component that includes a conversational UI, orchestration capabilities, configuration settings, and scalable APIs for copilots and LLMs. It embeds itself into everyday tasks and workflows for a more productive workforce and is grounded in the connected and contextual data and functionality our Decision Intelligence Platform offers.

Q Assist connects a customer licensed and deployed LLM and the Quantexa Decision Intelligence Platform. It works alongside Quantexa users, embedding itself into everyday tasks and workflows and is grounded in the full set of data and functionality our Decision Intelligence Platform offers.

Check out our Q Assist FAQs for more information.

Who can license Q Assist?

Q Assist is available in Quantexa Platform version 2.7 and is licensable as an add-on to existing Financial Crime, Fraud, Customer Intelligence, KYC, and Risk solutions. In this release, Q Assist is limited to customers in EMEA and North America for English Language deployments only.

*For more information on licensing and pricing please contact your Technical Account Partner or schedule a demo here.

Core components of Q Assist

This Generative AI Technology Suite is made up of 3 core components.

- Q Assist Copilot (Available in Early Access release)

An intelligent AI copilot that delivers instant, context-driven insights through natural conversation. The copilot works alongside Quantexa users revolutionizing how you work by surfacing critical data and context, streamlining repetitive and time-consuming tasks, and generating reports through a natural language interface. - The Prompt Library (Available in Early Access release)

A centralized repository of trusted prompts that standardizes data interactions, report writing, and investigation and research tasks across teams. - The Orchestration Layer (Coming soon)

Q Assist's orchestration layer is the “conductor”. A unified AI integration hub that streamlines data flow, coordinating multiple systems and workflows seamlessly. It ensures that user inputs are processed, and contextual data is incorporated from relevant platform components, and outputs are generated in a coherent, consistent, and explainable manner.

The orchestration layer handles tasks like:

- Ensuring that the correct context is applied to each request

- Retrieving and integrating information from multiple sources to enrich the response

- Coordinating workflows and routing requests to the appropriate models and platform components, applying business rules and guardrails, using an agentic architecture

- Integration with existing licensed or customer-built copilots

Q Assist in Action

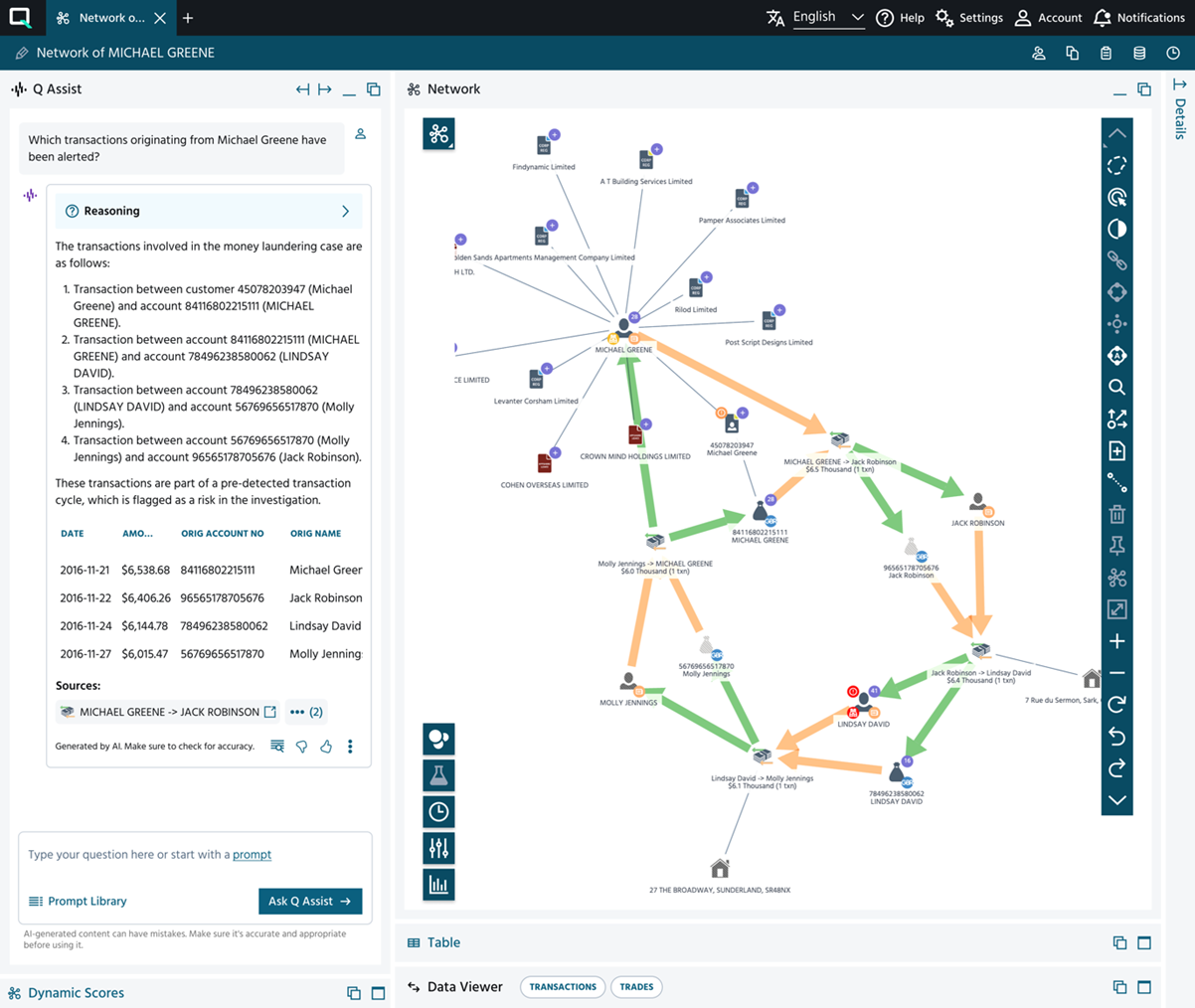

You can see Q Assist in action with our interactive demo in our Community Demo Hub and below we have highlighted some of the core features of Q Assist highlighting the benefits of each.

Research Assistance:

Q Assist streamlines access to a connected and contextual data foundation through an intuitive conversational interface.

This functionality empowers users to instantly retrieve critical insights by talking to their data. Insights about customers, counterparties, suppliers, transactions are available through natural language queries which informs more thorough and faster investigative and research processes with rich contextual insights.

By enabling self-service access to essential data, you can:

- Significantly reduce dependencies on dedicated data teams,

- Cut down manual research time while

- Deliver accurate and trusted information to those who need it when they need it

As a result, investigation teams, relationship managers, analysts can benefit from enriched data that highlights hidden risks and identifies overlooked opportunities, allowing for quicker resolution of complex cases. This level of immediate, detailed access not only accelerates investigations but also enhances relationship management and customer service productivity, leading to a more responsive and personalized customer experience.

Prompt Library

The Prompt Library feature in Q Assist is designed to centralize and streamline the creation, management, and sharing of trusted prompts across teams.

This tool allows you to build role-specific queries that can be easily reused across functions, ensuring that data interactions are both consistent and secure.

With the Prompt Library, you can:

- Foster controlled, repeatable workflows for decision-making

- Level the playing field across your organization—making every analyst as effective as your top performers

- Establish consistent and secure workflows that adhere to best practices and compliance standards

The Prompt Library empowers your teams to achieve optimal efficiency and alignment with organizational goals.

Report Generation

Q Assist’s Report Generation feature enables you to streamline the creation of a wide range of reports from SARs and EDDs to intelligence reports, risk assessments, and executive summaries, all with a single prompt.

This functionality uses predefined templates to build consistency in reporting for various types of reports, such as escalations and SARs, or even customer emails and talking scripts.

As a result, users can:

- Dramatically reduce the time it takes to create and process standardized reports

- Ensure data accuracy across multiple report formats

- Reinforce consistent and standardized reporting processes

- Reduce errors through predefined workflows

Overall, the Report Generation feature helps reduce the time spent preparing for customer meetings, ensuring that summarized information is readily available for strategic decision-making.

Contextual RAG

Q Assist grounds every AI-generated response in rich, contextual data, significantly reducing the risk of hallucinations and inaccuracies.

By anchoring outputs in relevant organization specific data and information, this feature

- Champions transparency with fully traceable and explainable responses.

- Increases trust and adoption internally

- Ensures you meet stringent regulatory requirements.

Each response is not only more reliable and accurate, but it also comes with clear explanations that empower users to understand the underlying rationale and data behind every decision, ensuring that data-driven insights remain both effective and explainable.

More information on Contextual RAG:

- Pre-recorded Webinar: Your AI Copilot is Only as Good as Your Data Foundation

- Blog post: Your AI Copilot is Only as Good as Your Data Foundation

Underpinned by the Quantexa Decision Intelligence Platform and tailored to critical industry use cases, Q Assist empowers teams to close the gap between data and decision igniting a more productive workforce.

Get in touch today to see how Q Assist can revolutionize the productivity of your frontline staff.

Quantexa Academy Plagiarism Policy

⭐ Content Overview |

|

|---|---|

🔗 Official Quantexa Academy Plagiarism Policy | To view the official Quantexa Academy Plagiarism Policy, please click here. |

ℹ Introduction

Within the Quantexa Academy, we are committed to upholding the highest standards of academic integrity in educating our employees, partners and clients on the solutions that are developed by Quantexa. The software that has and is being developed by Quantexa uses cutting-edge technologies, incorporating machine learning algorithms and Large Language Models (LLMs).

As part of Quantexa’s core values, we encourage our employees, partners and clients who participate within the academy to foster a learning environment driven by innovation, creativity, and of course ethical practices.

The Quantexa Academy Plagiarism Policy has been established to address plagiarism in the context of education related to the Quantexa Academy.

👩🎓👨🎓 Enrolling Candidates to the Academy

By enrolling in the Quantexa Academy, candidates agree to:

- Comply with this plagiarism policy and contribute to a culture of academic excellence and integrity.

- The work they are submitting is their own.

- They have not used any AI tools, such as ChatGPT for their work.

- They have independently developed the skills and knowledge required to pass each assessment.

📢 Reporting of Plagiarism

Any member of the Quantexa Academy who suspects plagiarism, whether involving code submissions or the improper use of AI-generated content, is strongly encouraged to report their concerns through the Quantexa Speak-up platform ‘Link to the platform’. All submissions will remain anonymous and will be directed to the Head of Education Services. All reports will be treated seriously and handled with the utmost confidentiality. Appropriate action will be taken following a thorough review.

If you believe someone is engaging in plagiarism or obtaining an unfair advantage unethically, you are encouraged to report this to ensure integrity and fairness within the programme.

⚙ Consequences of Plagiarism

If we suspect that a candidate’s submission has been copied from another person or generated by any AI solution:

- We will typically conduct a viva (oral examination) to test candidates understanding of the assessments/tasks they have submitted but also reserve the right to take another form of remedial action.

- If the candidate fails the viva, Quantexa reserves the right to take remedial action up to and including permanent disqualification from the Quantexa Academy.